Checkweighers

H Series

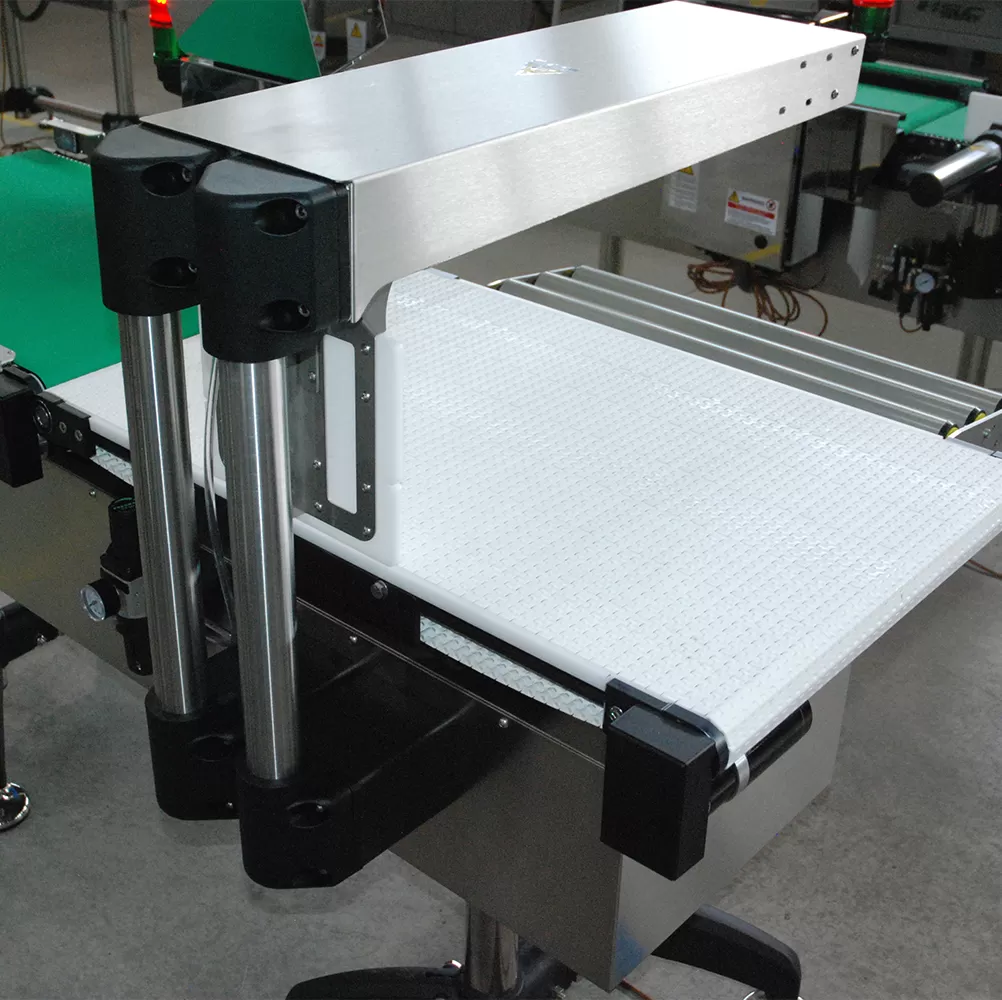

Ideal for bulky and heavy products

From 1.6 kg to 60 Kg - Maximum throughput 60 ppm

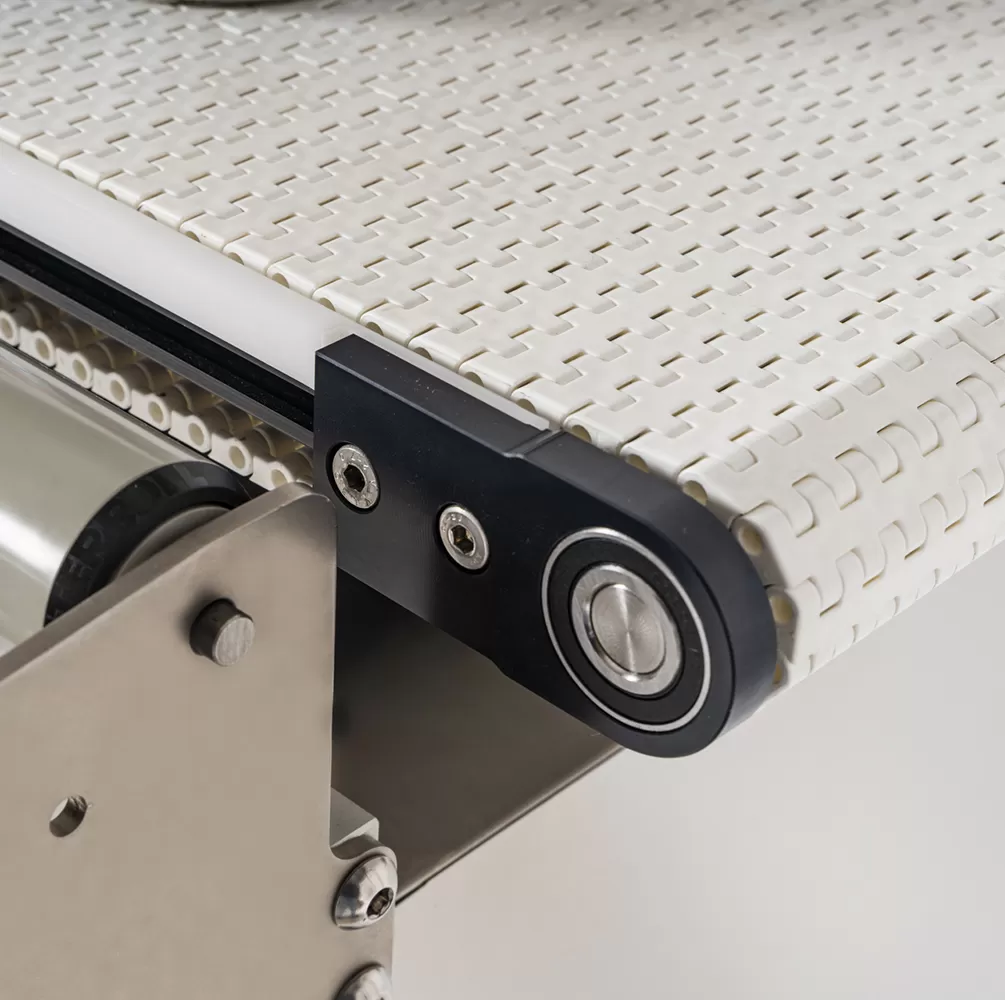

The sturdy stainless steel frame, the big conveyor rollers and the high-performing brushless motors allow to move and stabilize large and heavy products.

Best for logistics and chemical products.

The Nemesis sophisticate weighing software ensures high accuracy even with heavy loads.

From 1.6 kg to 60 Kg - Maximum throughput 60 ppm

The sturdy stainless steel frame, the big conveyor rollers and the high-performing brushless motors allow to move and stabilize large and heavy products.

Best for logistics and chemical products.

The Nemesis sophisticate weighing software ensures high accuracy even with heavy loads.