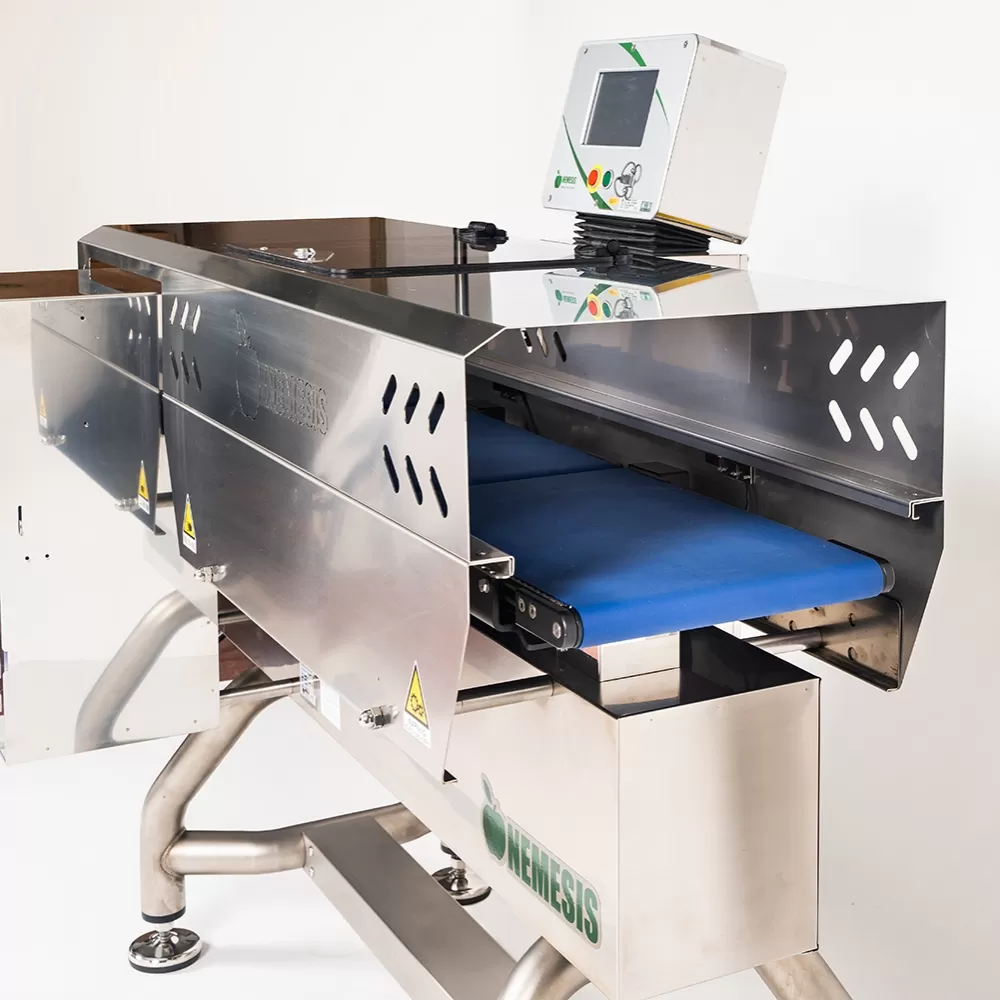

Checkweighers

D Series - for middleweights

In Retail version, if provided with stainless steel protection tunnel

From 300 g to 8 kg - Maximum throughput 120 ppm

It's the best solution to weigh packaged products with a wide range of weight and a 1 g scale interval.

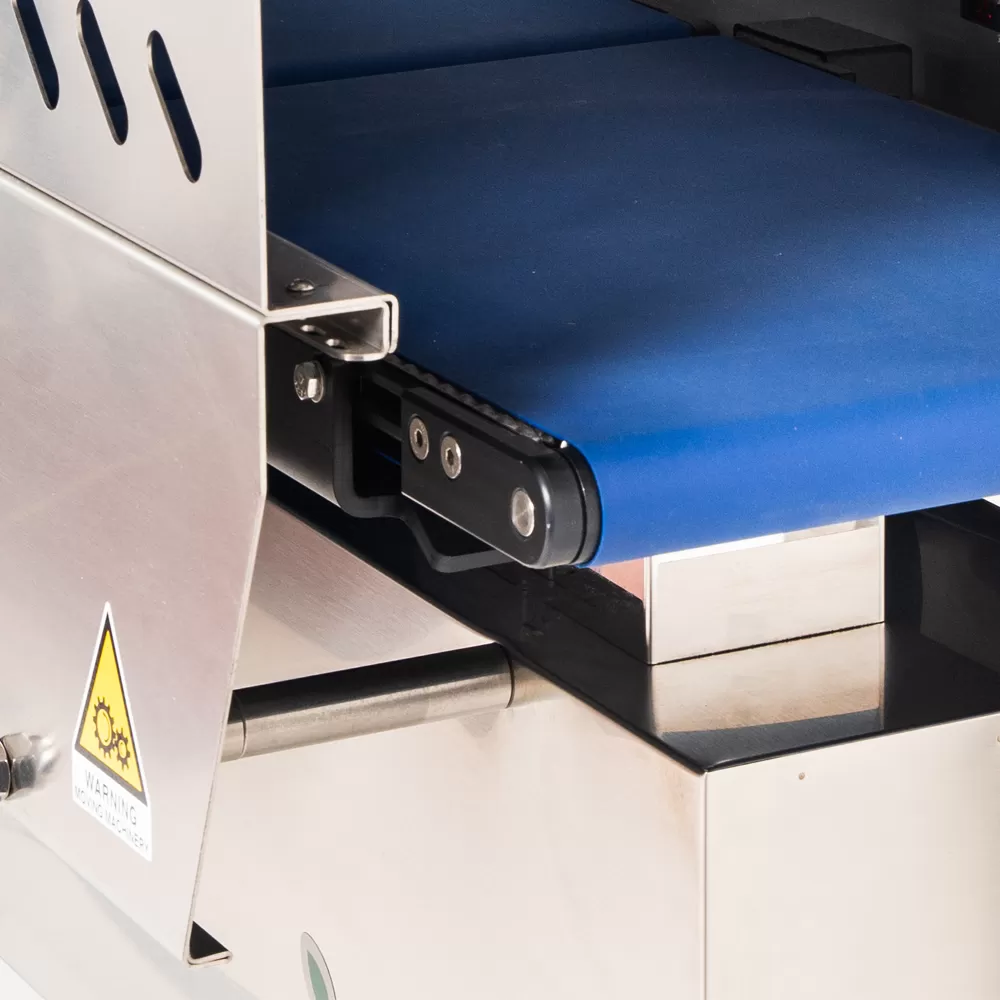

The stainless steel protection tunnel is an optional feature, and it is what makes it specially designed for the Retail i.e., compliant with the strictest occupational safety regulations imposed by some companies in the Large-Scale Retail, such as Marks & Spencer.

From 300 g to 8 kg - Maximum throughput 120 ppm

It's the best solution to weigh packaged products with a wide range of weight and a 1 g scale interval.

The stainless steel protection tunnel is an optional feature, and it is what makes it specially designed for the Retail i.e., compliant with the strictest occupational safety regulations imposed by some companies in the Large-Scale Retail, such as Marks & Spencer.