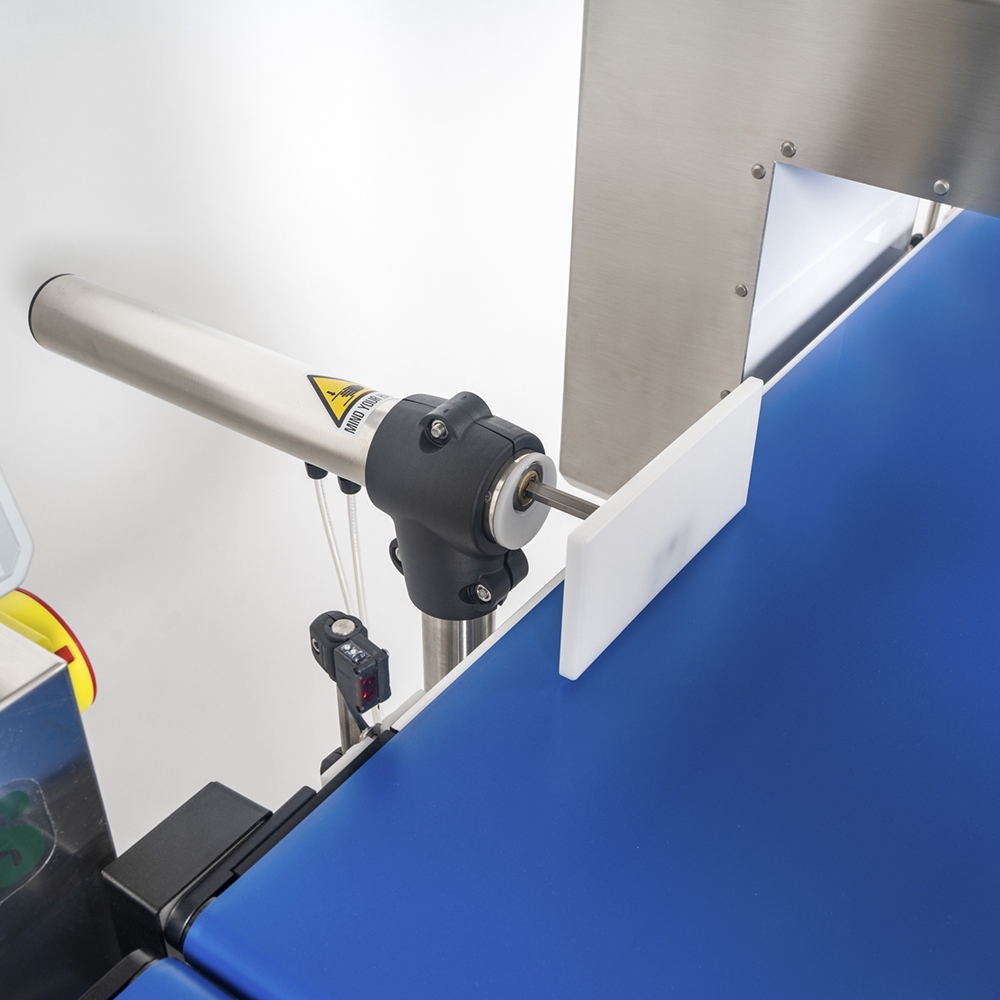

Metal detectors

MX Series

The combined metal detector + checkweigher

From 15 g to 60 kg - Maximum throughput 150 ppm

It is a total end-of-line inspection system for reduced spaces to simulteously weigh and find contaminants.

It complies with HACCP and GMP quality standards.

Available in Multi-frequency and Multi-Spectrum versions.

Download the catalogue

From 15 g to 60 kg - Maximum throughput 150 ppm

It is a total end-of-line inspection system for reduced spaces to simulteously weigh and find contaminants.

It complies with HACCP and GMP quality standards.

Available in Multi-frequency and Multi-Spectrum versions.