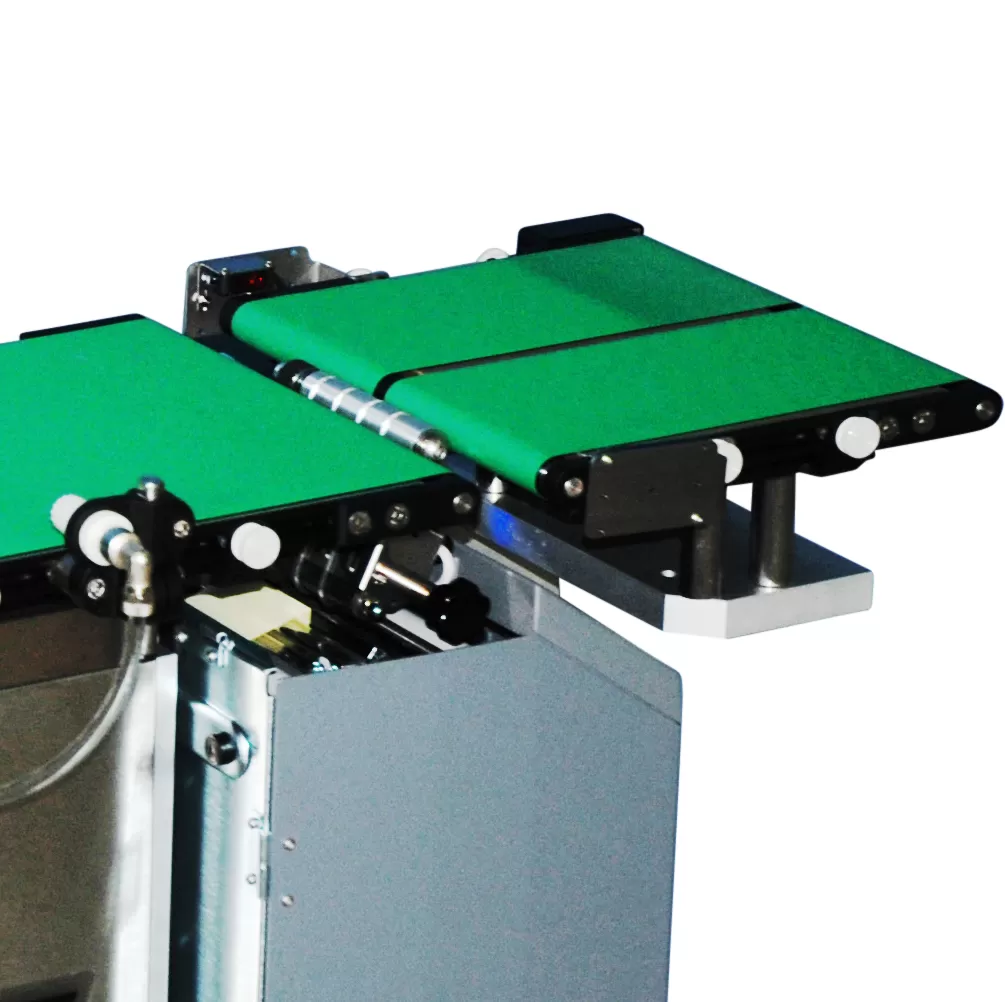

Weigh-Price Labelers

K Series Weigh-Price Labeler

A single machine for weighing and labeling

From 5 g to 30 kg - Maximum throughput 150 ppm

Easy to be integrated in existing production lines or to be used as a stand-alone station.

Available in several configurations, with different labelling options, from 1 to 5 conveyors to weigh and label any kind of packaged product

From 5 g to 30 kg - Maximum throughput 150 ppm

Easy to be integrated in existing production lines or to be used as a stand-alone station.

Available in several configurations, with different labelling options, from 1 to 5 conveyors to weigh and label any kind of packaged product