THE CHALLENGE

For a Pakistani company operating in the highly technological pharmaceutical sector, specialized in dermatology and ophthalmology, a request was made for a checkweigher capable of weighing 8-gram eye drop bottles on a packaging line running at a rate of 200 pieces per minute.

THE SOLUTION

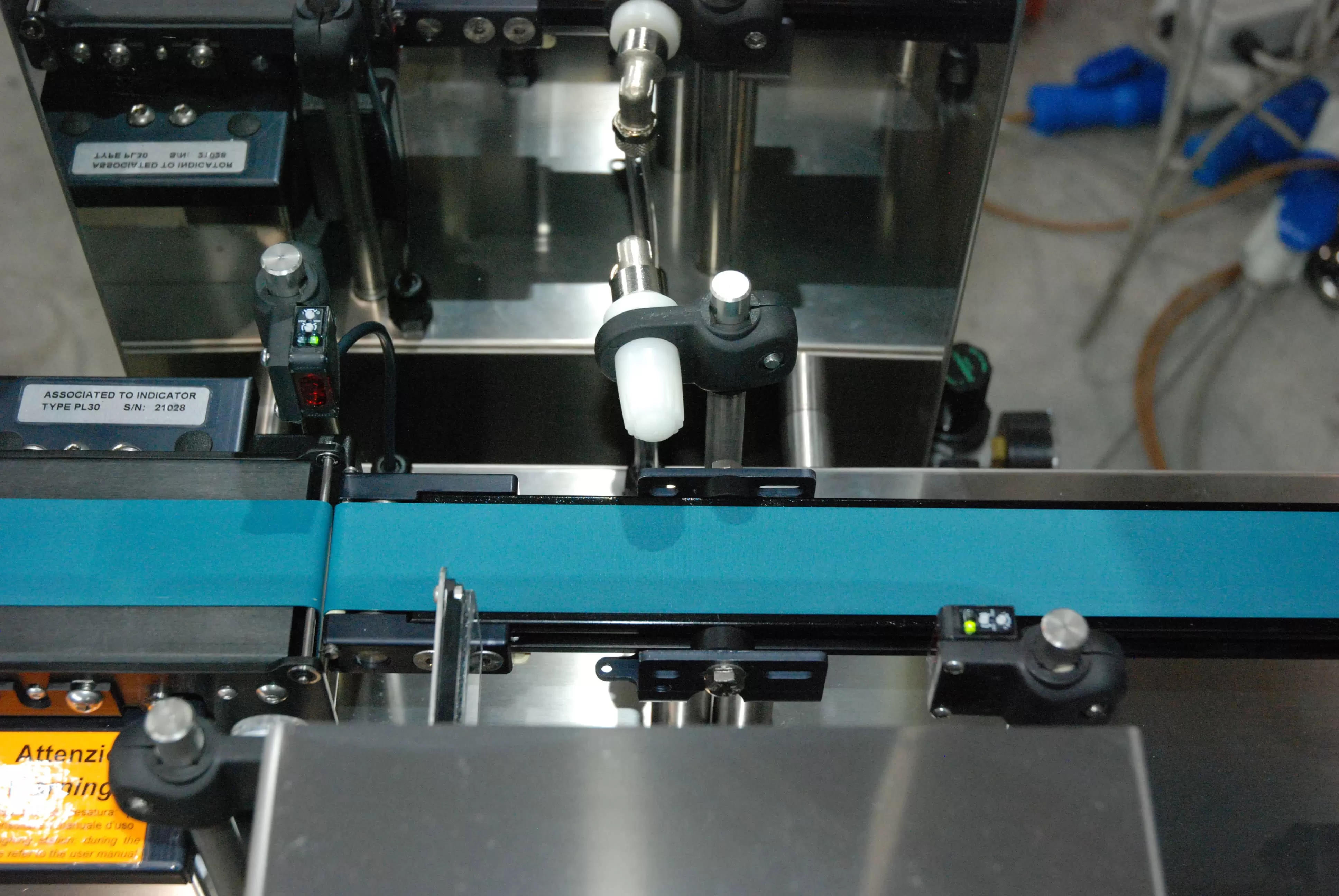

Nemesis designed and manufactured a S Series checkweigher for them, featuring microbelts with a width of 45 mm and support rollers with a diameter of 20 mm.

The machine has an extremely sensitive load cell capable of weighing the very light eye drop bottles with a scale interval "e" of 0.05 g. The display resolution is 0.01 g, allowing for setting tolerances in double decimal digits.

← Considering the lightweight nature of the eye drop bottles, the best rejection system for this application is the air blast one.

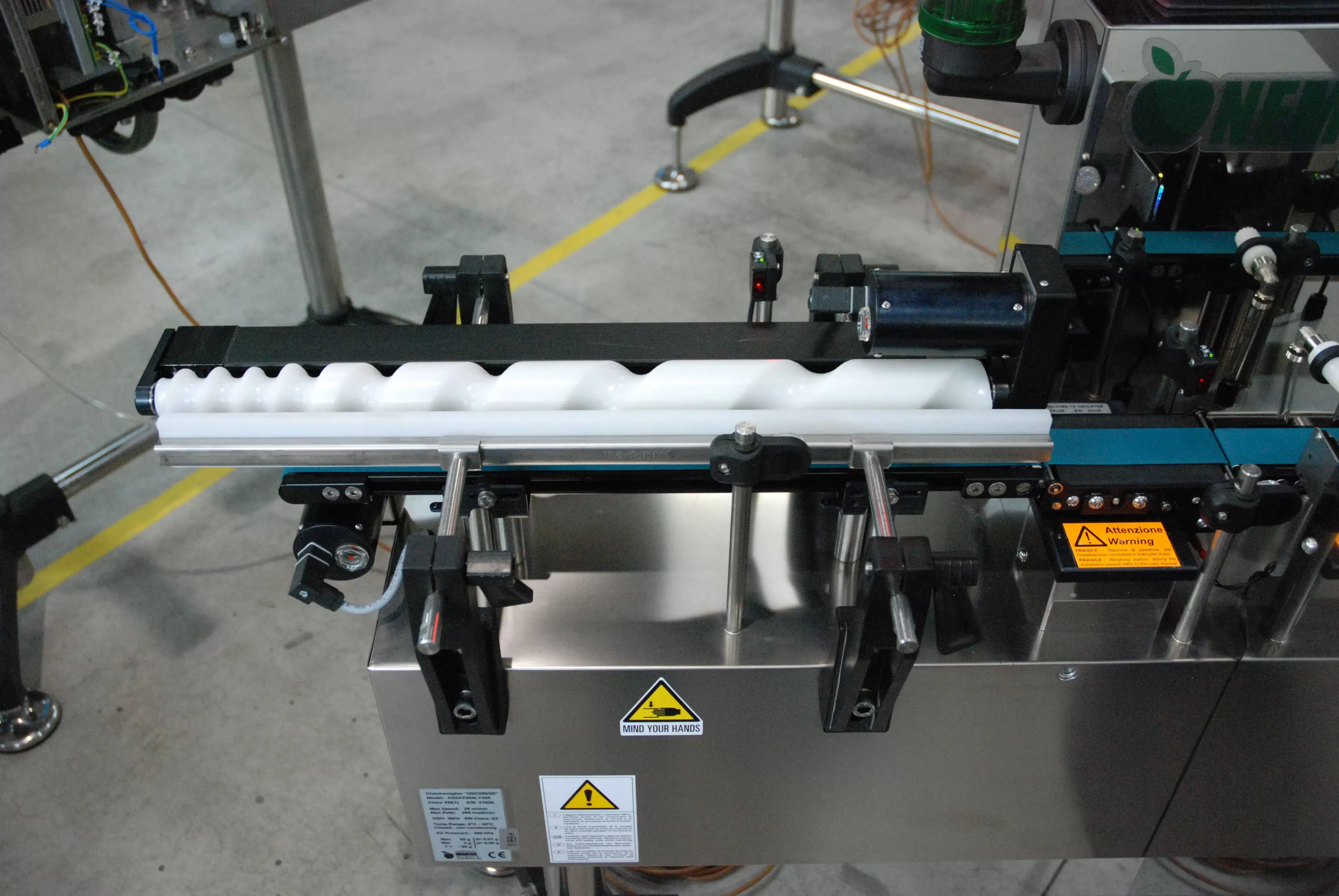

To ensure the correct pitch of the eye drop bottles, a feeding screw conveyor has been installed on the feeding conveyor. This guarantees the proper spacing between the products. →

THE BENEFITS

- The machine, conceived in this way, allows for the 100% inspection of the production of eye drop bottles with different shapes and weights, ranging from 8 to 13 grams.

- Despite the minimal base support of the bottles (maximum width of 23 mm) and their cylindrical shape, the polyurethane belts ensure stable and secure handling, enabling the machine to achieve the high speeds required by the company.

- The feeding screw conveyor on the feeding conveyor regulates the inflow of the bottles, even in cases where they are concentrated in a single point by the upstream process.