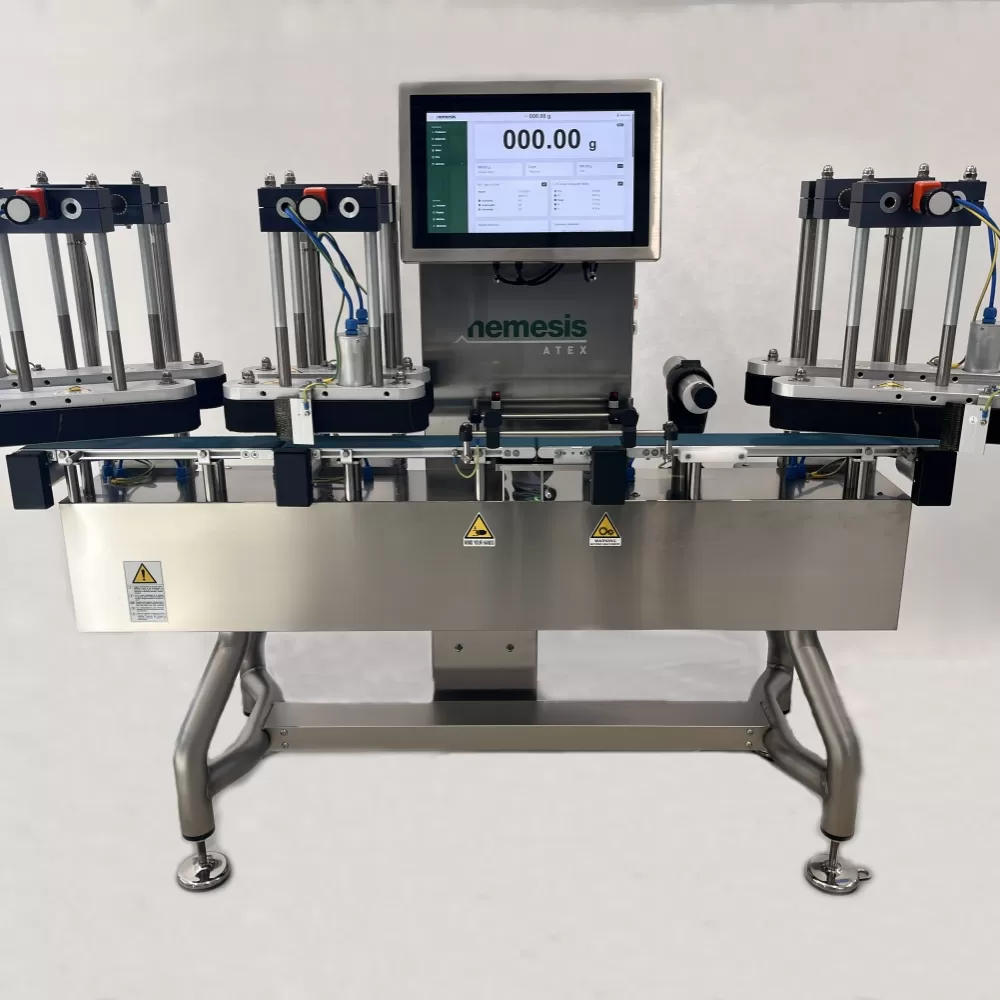

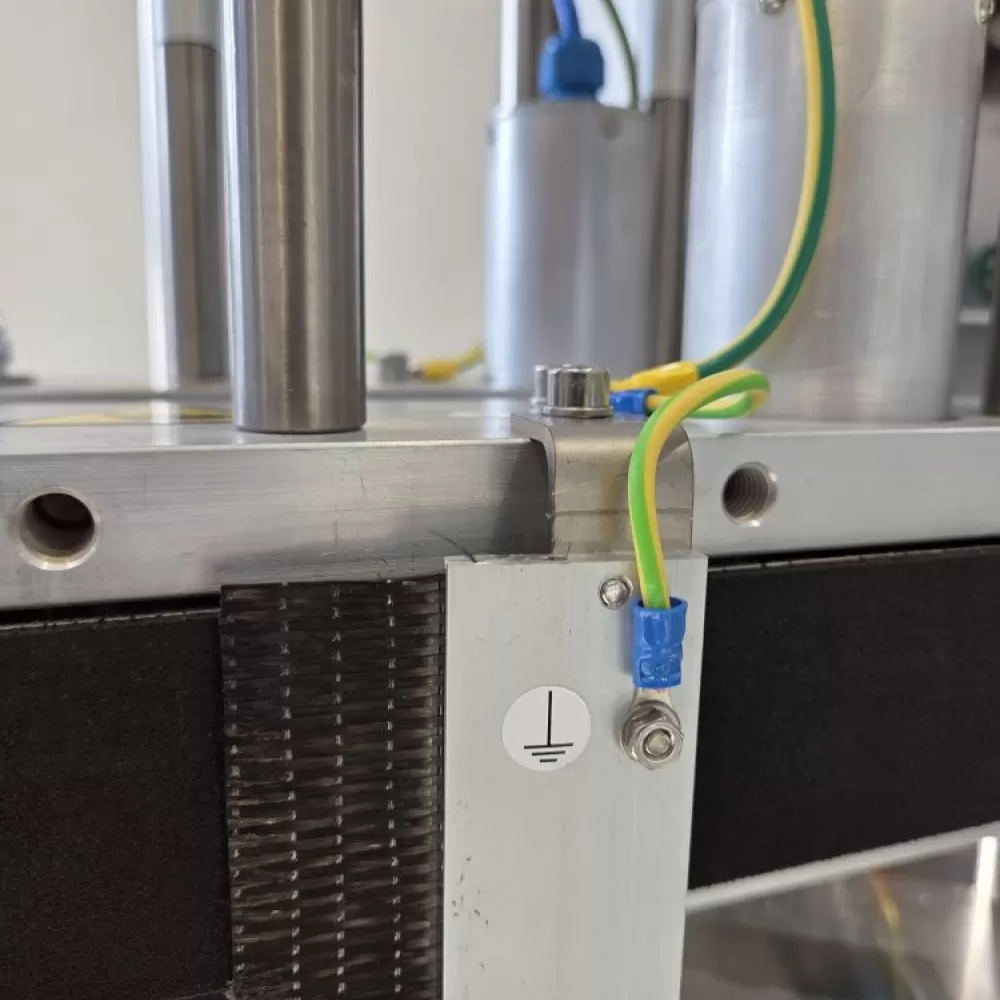

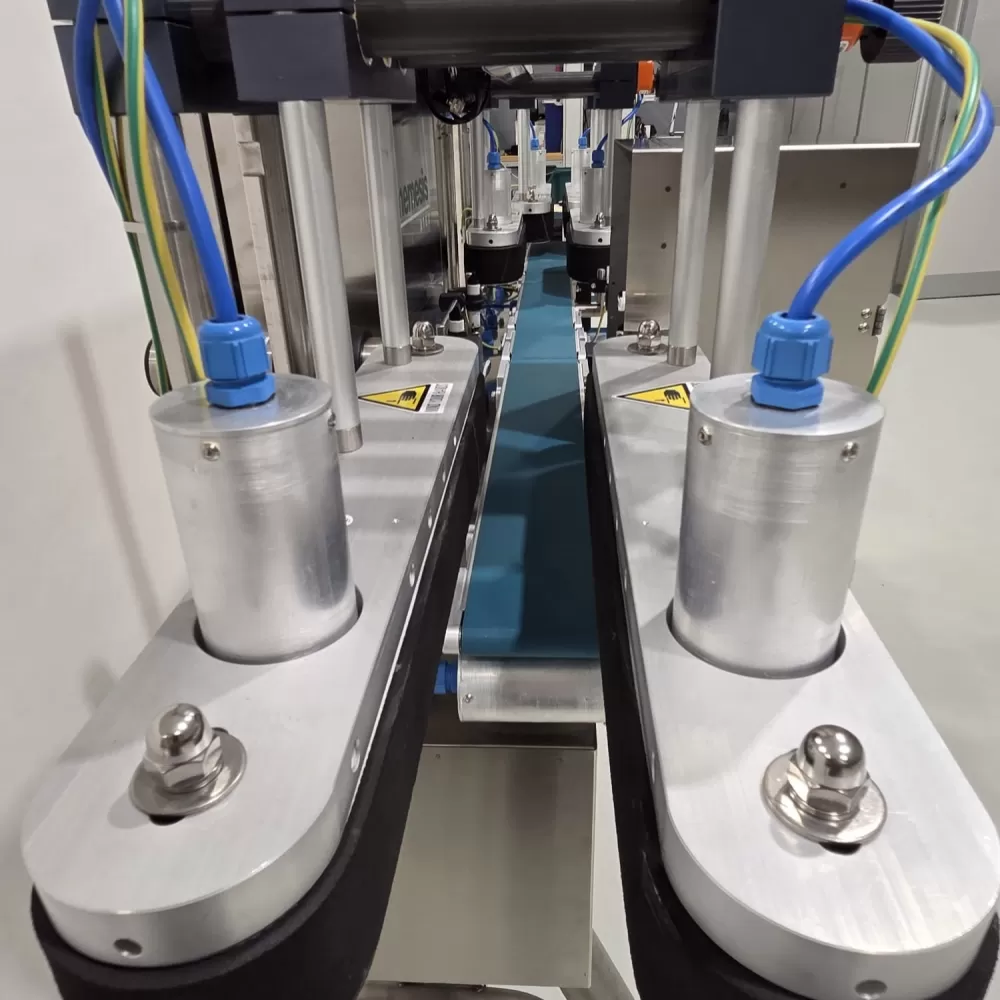

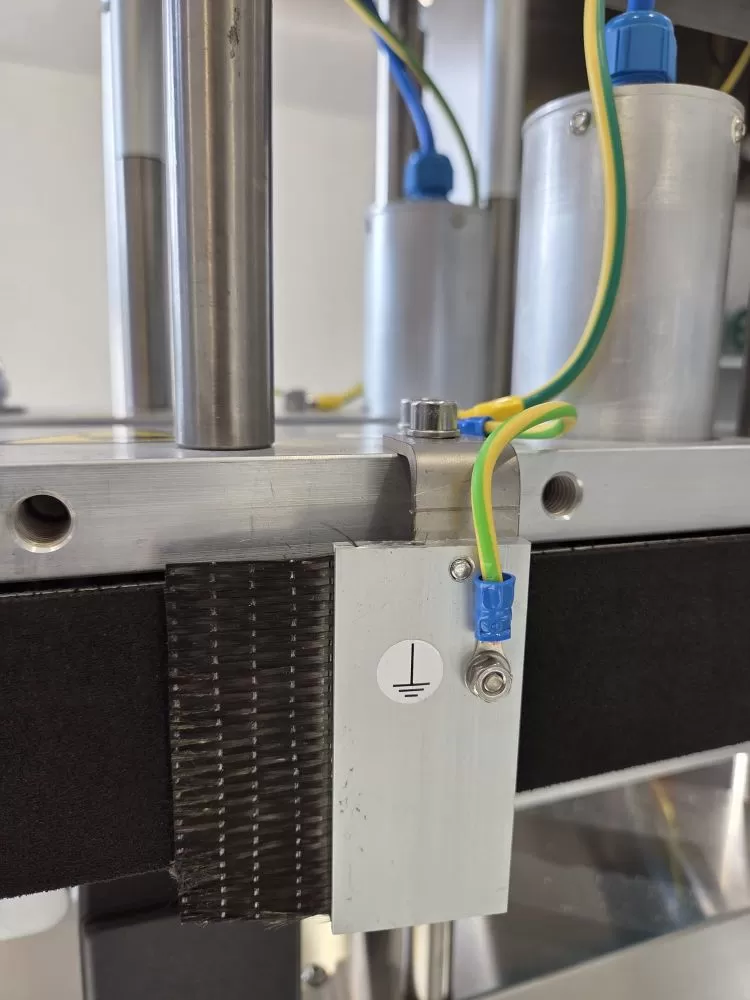

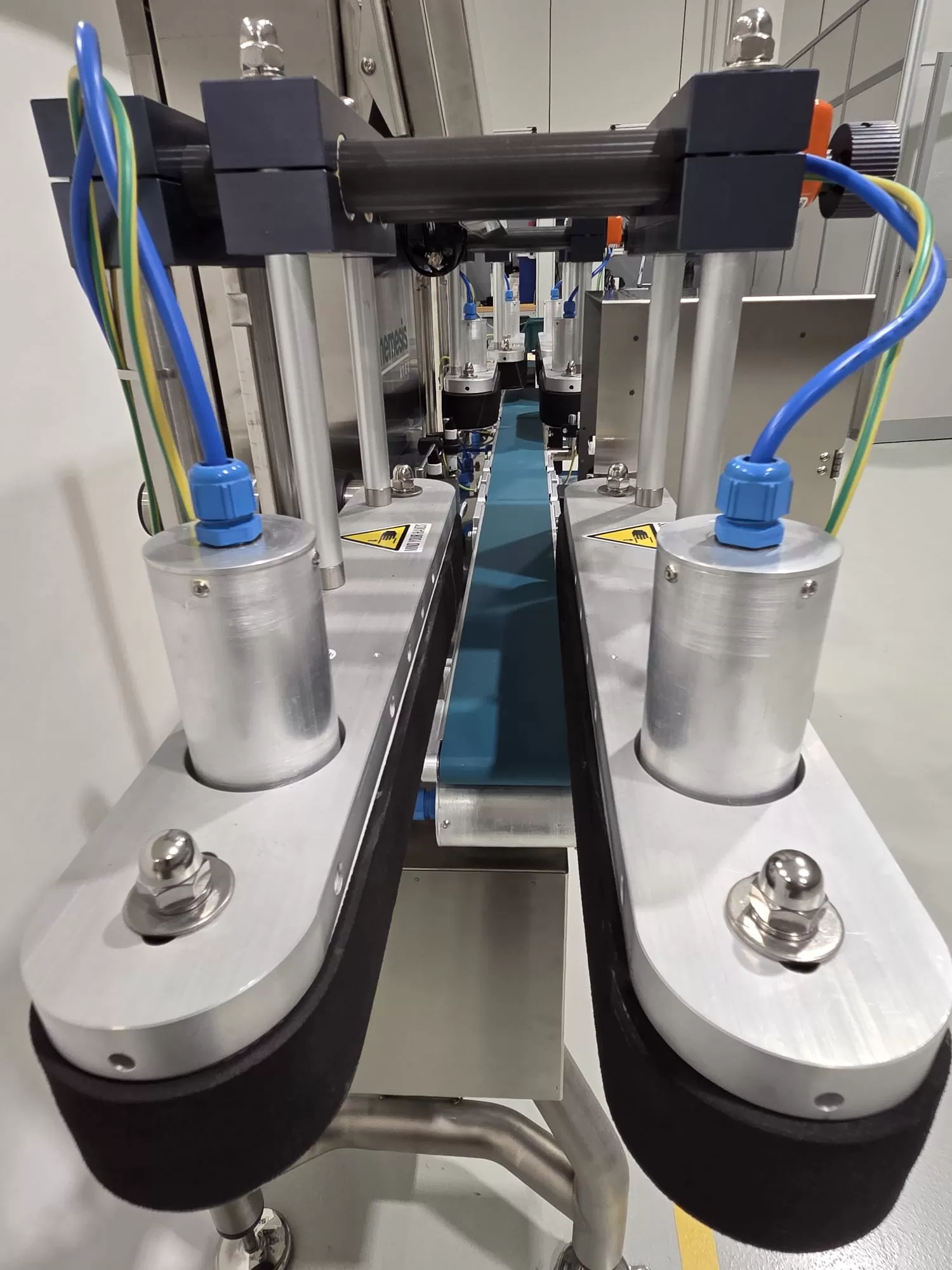

For a UK-based aerosol contract filler, a conveying, spacing, and dynamic weighing system for spray cans was developed for operation in a potentially explosive atmosphere due to the presence of combustible gases. This solution resolved the customer’s issues caused by a costly and inefficient star-wheel system that failed to weigh accurately and resulted in long machine downtimes during format changeovers.

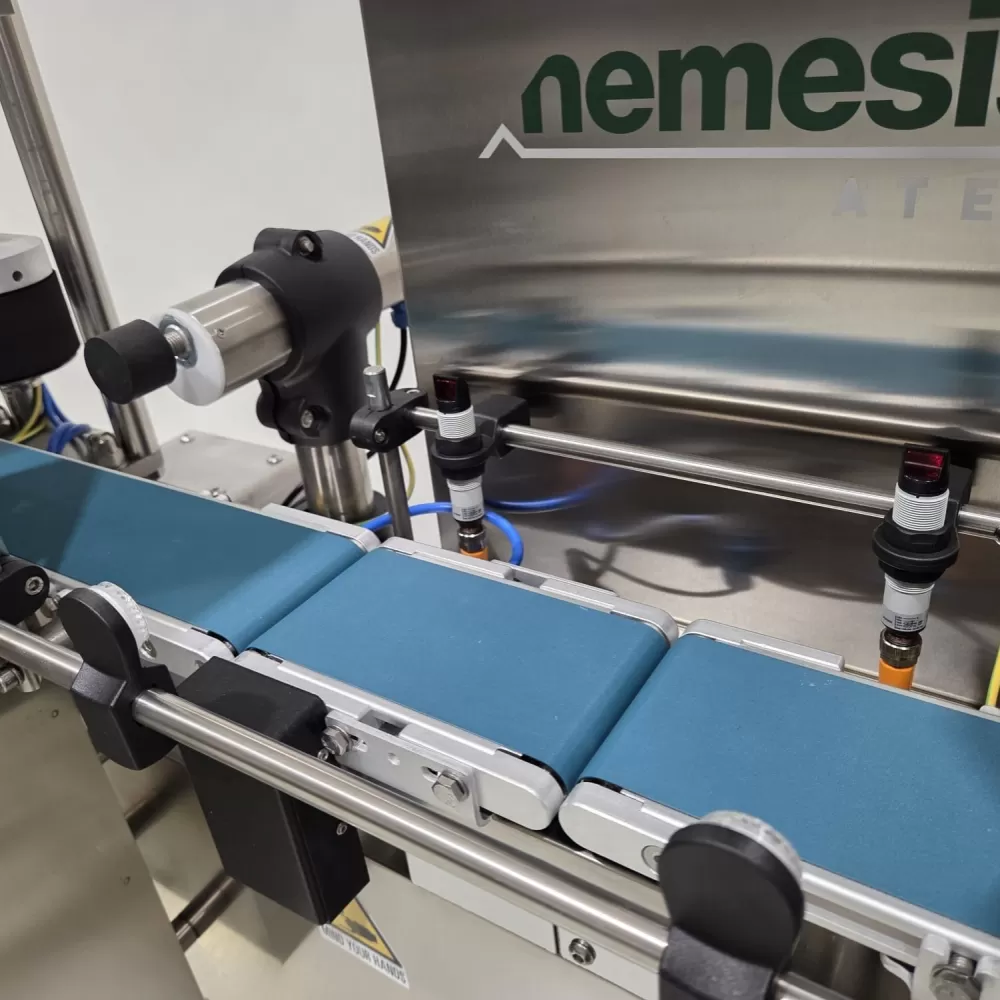

Nemesis’ ATEX solution, featuring infeed timing belts, also allowed the system to be installed parallel to the production line, eliminating the need to interrupt the line in order to integrate the checkweigher.