The metrological features

The machine can work with a minimum scale interval of 0.2 g, up to a number of 6000 scale intervals, with a belt speed up to 100 m/min and 3 different weight ranges.

Checkweigher | Scale Interval | Weight Range |

S Series | 0.2 g | from 5 g to 600 g |

C Series | 0.5 g | from 15 g to 3000 g |

C Series | 1 g | from 25 g to 6000 g |

H Series | 5 g | from 250 g to 30 kg |

The improvement of the scale interval in S Series checkweighers, designed for smaller and lighter products, is particularly appreciated in the pharmaceutical and para-pharmaceutical sector. Being able to detect missing or excess weights of 0.2 g is crucial in achieving a very high weighing precision and, consequently, product quality.

One of the industries that needs to combine precision with high production rates is the pastry, snack, and bakery industry in general. The new MID certification can provide them with the right sorters to weigh with 0.2 g accuracy on conveyors traveling up to 100 m/min.

The ability to now set the same machine on three different weight ranges makes it extremely useful in cases of highly heterogeneous products. The introduction of this multi-scale feature represents a significant innovation for the industry.

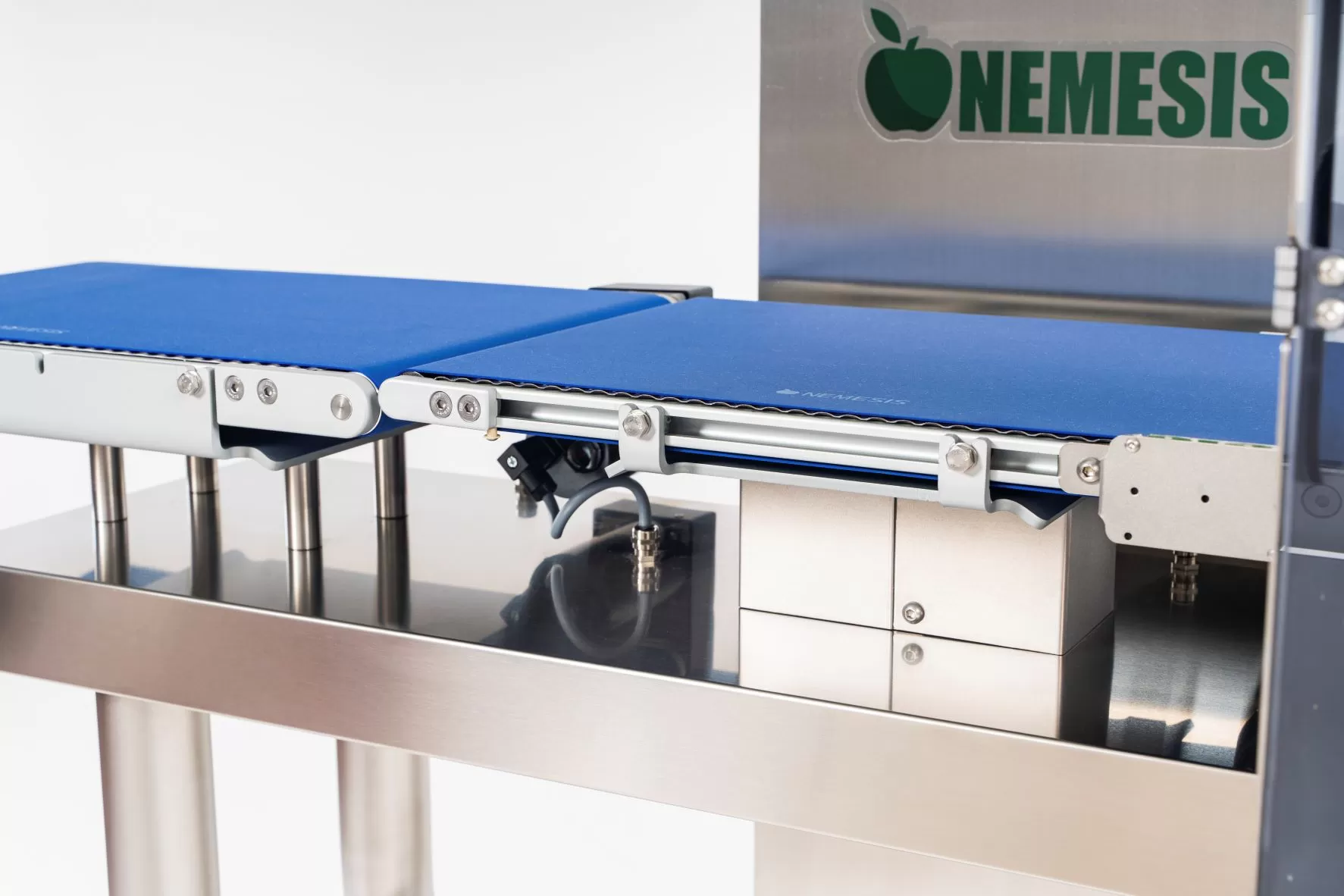

The new architecture and all its benefits

Upon request, the new “NEXT” certification can be paired with a redesigned machine architecture.

Reimagined to be more robust and durable, it features a slimmer and more compact design, making the checkweigher easier and lighter to manufacture, handle, and ship. This characteristic significantly reduces its environmental impact, making it more sustainable.

Easier to sanitize

The entire frame of the machine is made of stainless steel, the material with the highest guarantee of hygiene and the lowest risk of bacterial contamination.

The elimination of traditional casings, combined with its smooth and uniform surfaces, makes the structure extremely easy to clean.

Better protected loading cell

We have modified the load cell assembly to make it more robust and capable of withstanding any accidental impacts, including lateral ones.

A 15'' thin display

We have increased the size of the control panel by incorporating a minimal design 15-inch touchscreen display to enhance visual impact and align with the new usability requirements of the market.

More robust conveyor belts

To enhance the robustness of the conveyor belts, we have increased the roller diameter to Ø30mm in the infeed and outfeed belts, ensuring the best weighing precision while protecting the machine from external mechanical factors.

Larger case for wiring

The electrical panel of the new NEXT architecture is characterized by its large dimensions, providing a robust case capable of accommodating electronic boards and wiring, even from other integrated machines. This not only adds solidity to the machine itself but also allows for the integration of components from other systems.