Weigh-Price Labelers

K Series Weigh-Price Labeler

A single machine for weighing and labeling

Weighing + Labeling

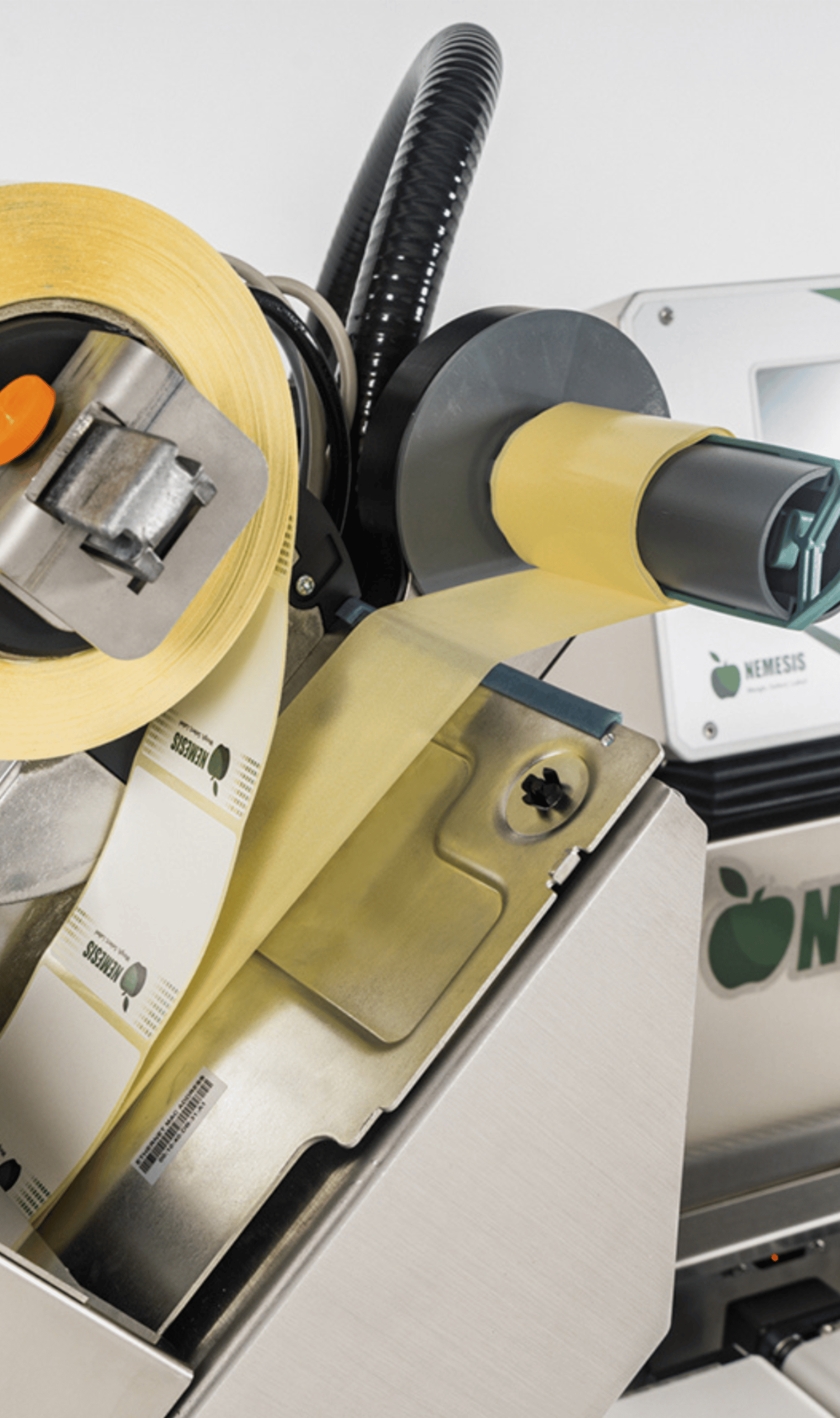

The Weigh-Price Labeler is a combination of a checkweigher and one or more labelers. After weighing the product, it can transmit the data (weight, price, expiration date, manufacturer information) to the printer, which is then printed on the label. The label is subsequently applied to the product by the printer itself.

Considering the extremely tight timelines between these various stages, the printing process occurs virtually in real time.

To allow maximum freedom in label design, Nemesis provides a laptop along with the weigher-labeler on which two programs are already installed: NiceLabel for graphic label creation and SAVUltra Editor, a Nemesis proprietary software for program management. SAVUltra Editor harmonizes the label graphics with the weighing data obtained from the scale and then sends the print signal to the printer.

With SAV Ultra Editor, it's possible to create and store up to 9999+ product/PLU programs. This makes the machine startup simple and fast, thanks to the pre-installed and configured software. To train the user on software usage, a personalized technical course is organized.

There are different types of weigh price labelers, depending on the desired label type, where it should be applied, or if more than one label needs to be applied.

This is the most standard version. Thanks to a pneumatic group, the label produced by the printer is blown with an air jet above the product. It is the simplest application. The product should not have particular criticalities, and the surface and dimensions of the product must be suitable for this type of machine.

In the case of a more complex product, the pneumatic piston labeler is used. Here, the label is suctioned by the piston, approaches the product without touching it, and is then shot with compressed air from a very close range. This application system is known for its extreme precision. There is also the version with a contact piston. In this case, the piston reaches the end of its stroke by touching the product. It is a more invasive system and is suitable for resistant products.

Here, the printer and its corresponding application group are mounted under the conveyor belts and placed between two exit belts. Therefore, the machine has four belts, including 2 exit belts. The applicator group can be equipped with motorized belts, which lift the label upward, ready to attach to the product when it passes over the belts. The same applicator can also be equipped with idle rollers, non-motorized, where the label waits for the product. When the product passes over it, the label is dragged and attached.

Similar to the Top one, this label applicator can use compressed air or a piston. The label is applied to the side of the product. The most common type is the piston version because the air-driven labeler is usually less precise, and applying it horizontally is extremely difficult.

This application is usually required for large products, boxes, crates, etc. For this purpose, a pneumatic, tilting paddle is used to grab the label from the printer and apply it to the front. Of course, this application is slower.

It is the machine for applying a "C"- or belt-shaped label, which is thin and very long, embracing the entire product from below to above.

To achieve this, two motorized belts installed side by side are required, gripping the product, supporting it, and bringing it to the center of the applicator where the belt descends onto the product.

In the case of round products such as watermelons, melons, or similar items, the machine must first have 2 twin inclined V-shaped conveyor belts, allowing easy control and transport of the product. The label applicator will be an upper printer with label application using a compressed air jet.

Depending on the production needs, combined versions of weigh-price labeling machines can be created by combining different application systems: C and Upper, Lower and Upper, etc. When there are more than one printer, both can be connected to the scale, or only one of the two. In the latter case, the second will print a label containing only general information without weight or price. All Nemesis Weigh-Price Labelers work with the same type of thermal label that turns black when heated, generating text.

There are two techniques for heating the label in thermal printers:

The choice of the type of printing depends on the application and the product to be labeled. "Nemesis Weigh-Price Labelers" are suitable for both printing systems, so it's a customer choice.

To define the right Weigh-Price Labeler, it is necessary to clarify some essential requirements:

Considering that there are printing times to respect, the larger the label, the fewer labels can be printed per minute.

The edges of the label are usually pre-printed, but if it is necessary to print even in the outermost edges, the machine must provide BACKFEED, i.e., the label must re-enter the printer for the second printing pass.

The labels are attached to a support paper and wound in a roll. Winding can be internal or external depending on the positioning direction. It is a crucial aspect because it determines the curvature the label takes, especially as the roll is depleted and goes towards the inside of the roll. Here, the labels bend a lot, and depending on the application system, it can become more difficult to attach them to the product.

Nemesis recommends rolls of labels with internal winding because it is easier for the machine's applicator to suction a concave-shaped label than a convex one.

Each type of machine has minimum and maximum label dimensions to print. Below or above a certain dimensional threshold, the application group cannot pick them up and apply them. There is an optimal size range with which the machine reaches maximum speed. If the label is too large, the process is slowed down, or it may risk getting stuck.

In the case of labels larger than approximately 100 x 120 mm, it is advisable to use the top piston applicator because the size of the label is one of the factors that makes it more volatile in the air. A large label is also more volatile, reducing the precision of application. If a label is required as large as the product, it is essential to carefully evaluate the minimum and maximum limits.

Related products

We'll be happy to follow-up your request within 24 hours