THE CHALLENGE

The meat processing company Eat Meat in Castelnuovo Rangone (Modena, Italy) works and packages high-quality meats sourced from around the world. It supplies the restaurant industry, Horeca channels, and the Retail Trade throughout Europe, recording an annual sales volume of approximately 2,500 tons of meat.

They approached Nemesis for a checkweigher to weigh beef fillets and burgers with a maximum weight of 400 g before being packaged in the appropriate trays.

THE SOLUTION

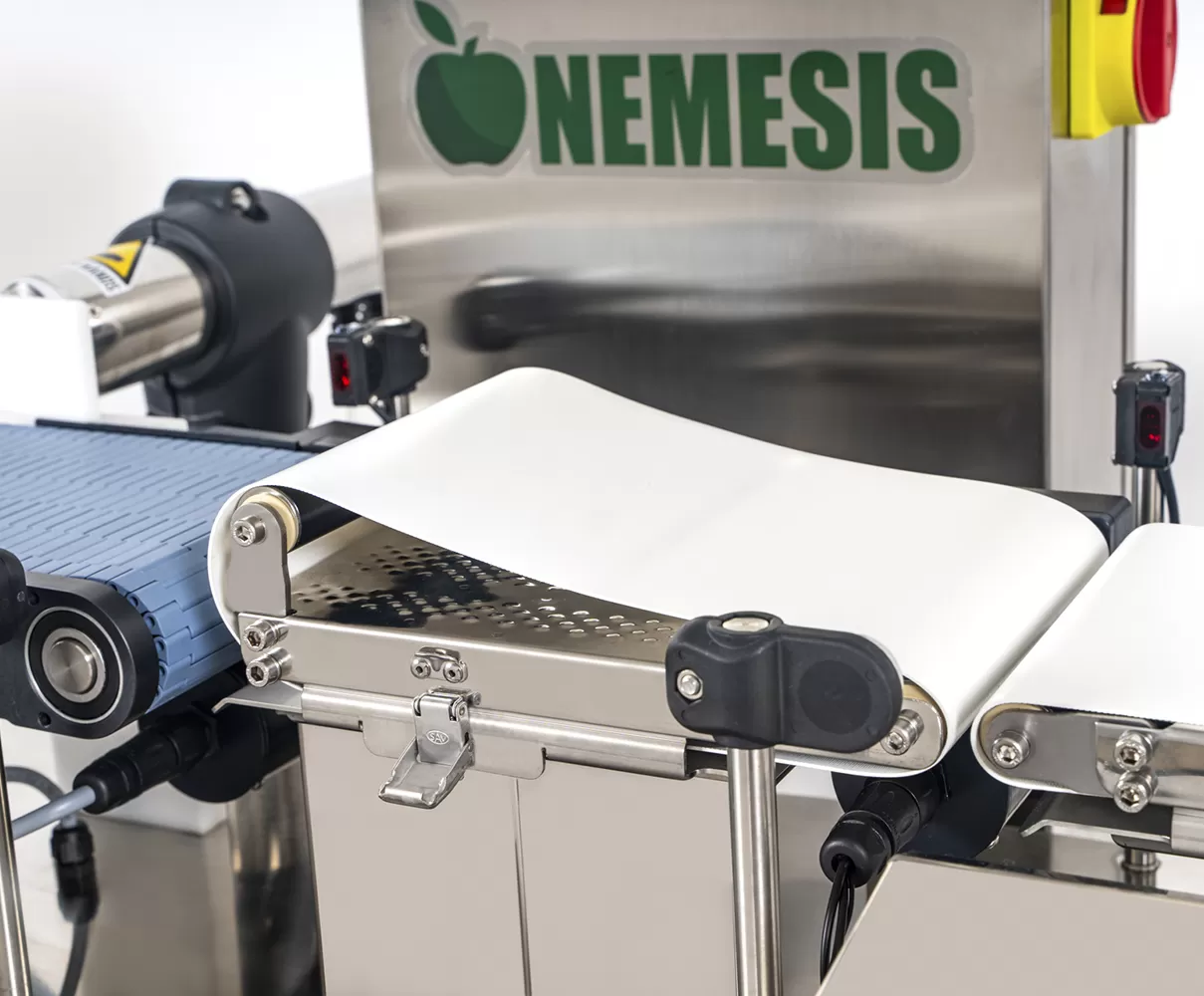

To meet the customer's needs, we have specifically designed and implemented a G Series Checkweigher built with special materials for the belts and the ejector, suitable for contact with food.

Operating at a throughput of 120 pieces per minute with a weighing accuracy of 2 grams, the machine weighs 100% of the meat passing through the line, ensuring its correct compliance with the set weight tolerances and rejecting non-conforming pieces that are either over or underweight. The rejected pieces are then reintroduced into the production process and reworked.

The belts of the G Series checkweigher are constructed with a smart architecture that allows for easy disassembly and removal of the belts for cleaning at the end of production. The machine's water penetration protection level is IP66, one of the highest on the market.

THE BENEFITS

- Considering the high cost of the processed product, precision in meeting the weight of the packages is crucial to avoid overfilling and giving away the product. Additionally, complying with the net weight indicated on the packaging, in accordance with EU Regulation 76/22/EEC and Law 690 for packaged products sold in the Retail distribution, helps avoid penalties and damage to the brand's image. To further analyze this aspect, we recommend reading the section on the Savings Simulator.

- The machine's belt disassembly capability makes cleaning much simpler and immediate.

- The rejection system with a pneumatic pusher adheres perfectly to the polyurethane belt, facilitating the dragging and expulsion of the meat piece.