THE CHALLENGE

Vongoplà is a Romagna-based company that packages fish and shellfish for sale in Retail distribution.

Their main challenge has been to develop an immediate packaging method to keep the packaged fish fresh for long periods, ensuring hygiene and traceability for the consumer. Following the highest hygiene standards, the fish is complemented with seasonings from the ancient maritime tradition—true and genuine flavors derived from over twenty years of experience.

The company approached Nemesis for a weigh price labelling system capable of weighing the trays and simultaneously printing and applying a long label. This label serves the dual purpose of sealing the package and conveying a large amount of product information, including the logo, expiration date, and price.

Nemesis designed and built a special K Series weigh-price labeling system for them, featuring a "C"-shaped label application.

It consists of a checkweigher with a scale interval "e" of 1 gram capable of weighing and rejecting, if non-compliant, trays up to 1.5 kg. Additionally, it includes a Honeywell printer that prints the long label requested by the customer and applies it to both the lower and upper sides of the tray, embracing it.

The brush

To achieve the sealing effect, under the printing group, a special brush has been fitted.

After the printing and application of the adhesive band, it ensures its perfect adherence to the plastic packaging.

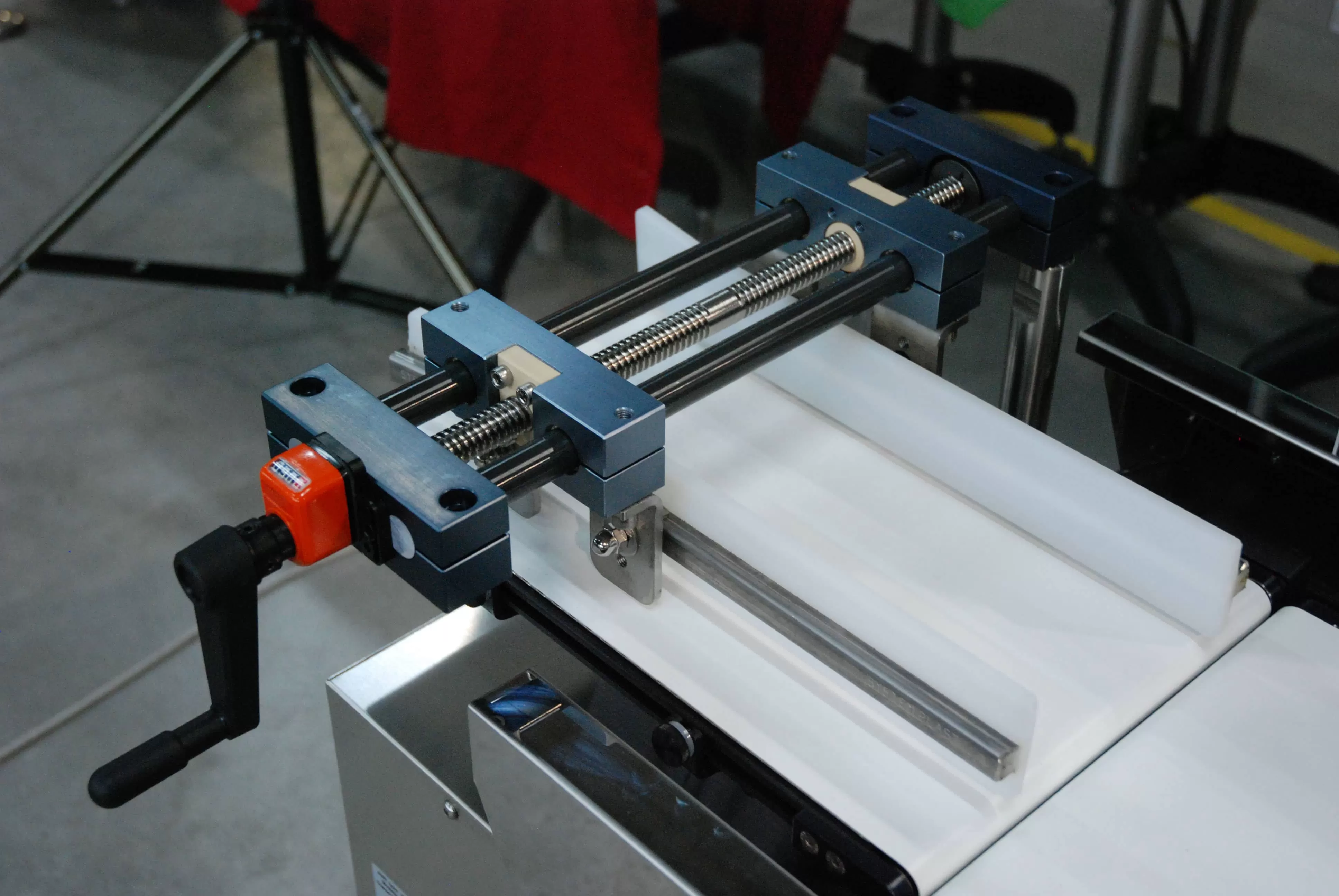

Guide railings

To keep the trays perfectly aligned from the entrance to the exit of the machine, lateral guides have been provided. These guides can guide the trays to the center of the conveyor belts and keep them perfectly centered with respect to the labeling group, after the weighing.

In both positions, the guides are equipped with a micrometer to adjust the distance between the two guides with sensitivity to the hundredth of a millimeter. This ensures support and guidance for the trays, which, depending on the packaged product, may have different sizes.

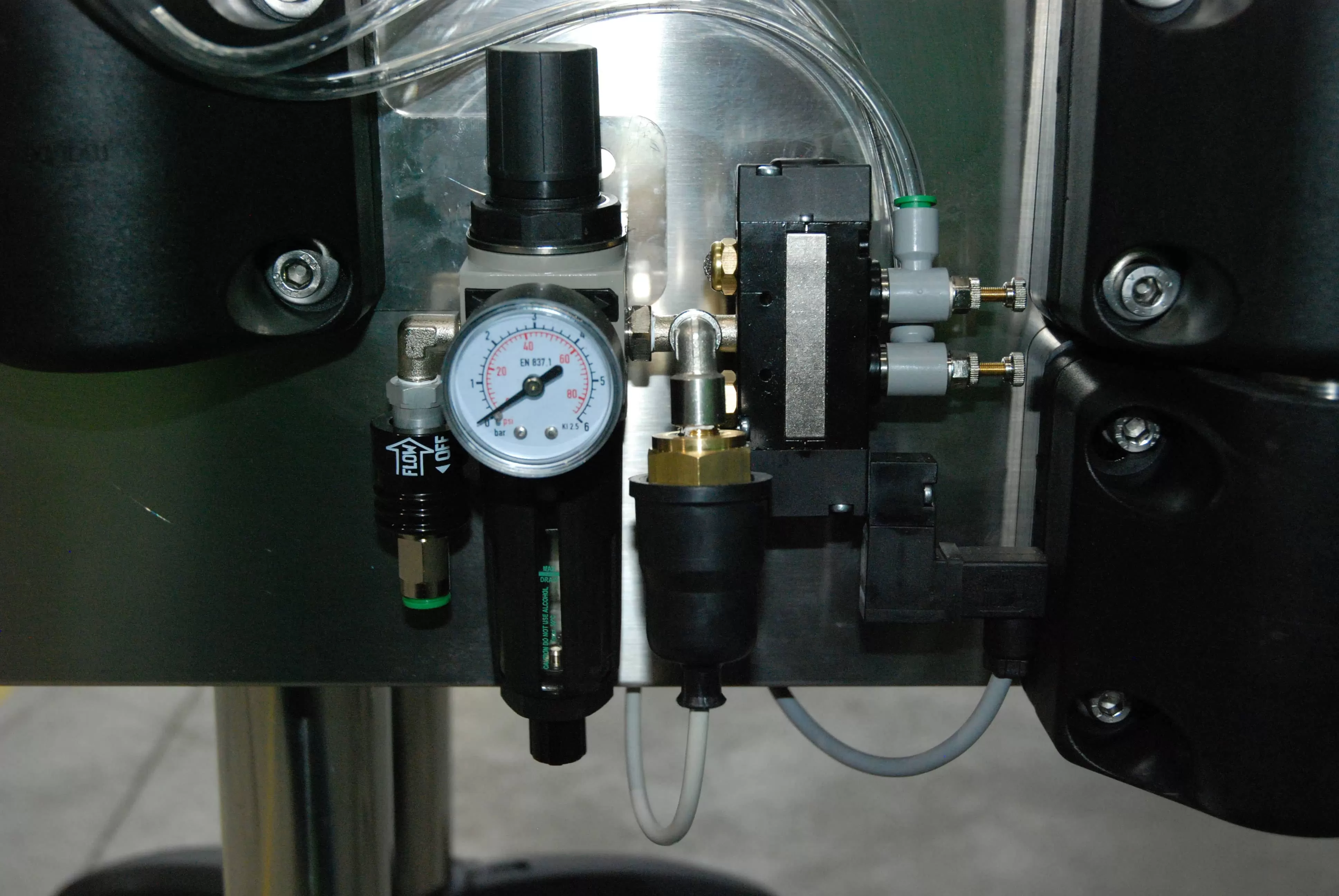

As an additional safety system, a pressure switch is installed. Its function is to detect and signal any drops in compressed air pressure in the circuit that operates the labeling group.

At the machine's exit, an idle roller conveyor unloads the trays suitable for sale, ceating a accumulation on a platform, a work surface, or inside a box

THE BENEFITS

- In just over a meter and a half in length, the Nemesis weight-pricer represents an efficient and compact system for weighing and labeling fish trays.

- The installation of the ANALYTICS software package allows the producer perfect traceability of all production batches, as well as comprehensive reporting to monitor the line's efficiency.

- The machine's MID certification makes the product sellable in large retail stores because the weights detected by the instrument and printed on the label have legal value.

- The "C" label application system, equipped with lateral guides, is an excellent solution for applying long and information-dense labels.