What are IP Protection Ratings?

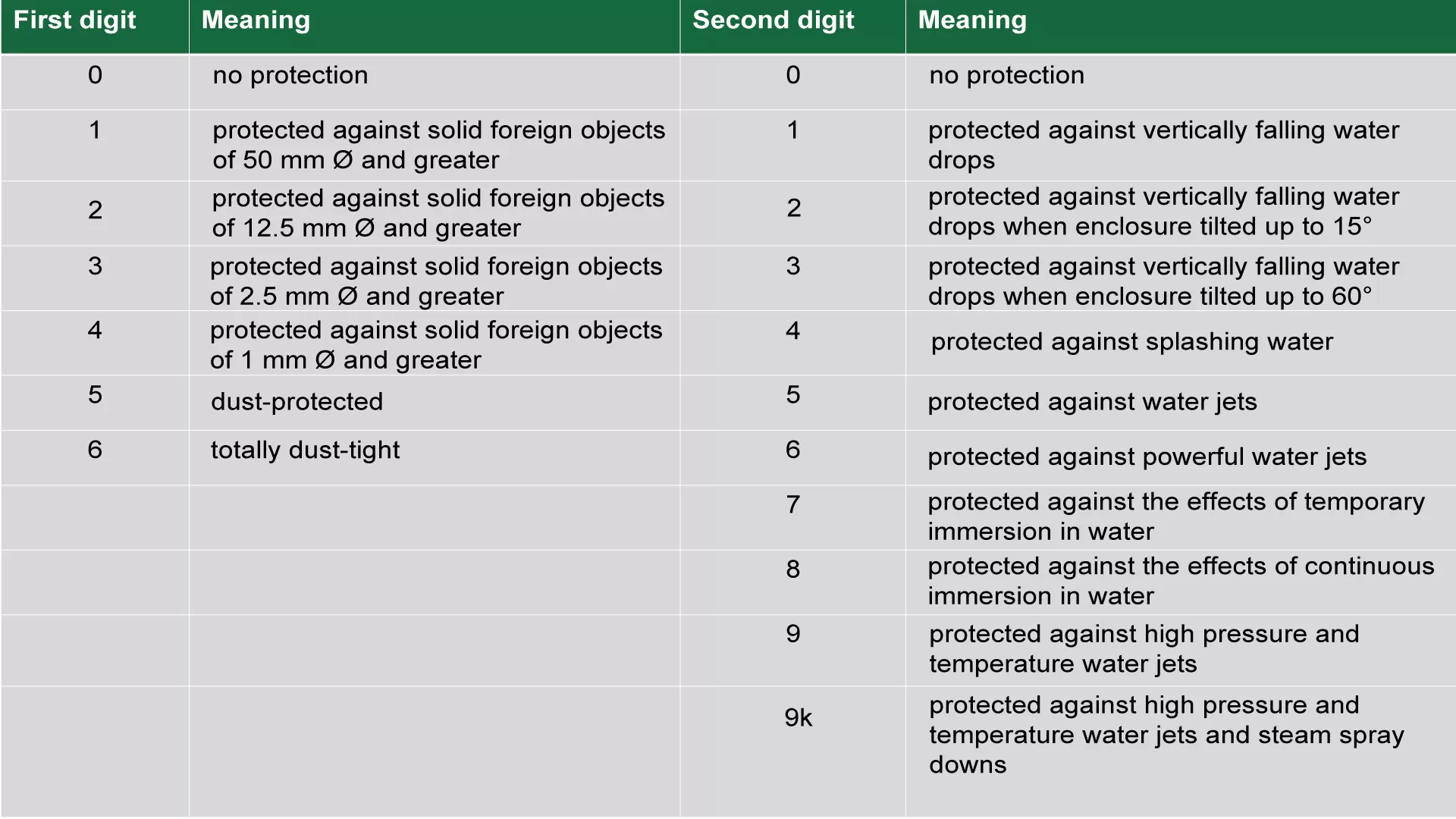

The IP protection rating is a parameter defined by the international standard IEC 60529 issued by CENELEC (European Committee for Electrotechnical Standardization), which classifies machinery and electrical enclosures against the intrusion of solid particles, dust, and liquids.

The associated tests are therefore part of the electrical safety verification of a product, as they are specifically designed to protect electrical components against external agents.

Ingress Protection

To certify the IP rating of a machine, its components must be laboratory tested to verify resistance to the ingress of dust and water.

All Nemesis checkweighers have a basic IP54 rating, meaning the frame and components are designed to prevent dust intrusion and can be cleaned with a damp cloth and light water sprays.

If the application or working environment requires it, with the replacement of certain parts, they can be upgraded to IP65, which means they are completely dust-tight and washable with low-pressure water jets.

In cases where the production environment is particularly humid and the belts come into direct contact with food, such as in meat or fish processing, the checkweigher must be constructed to IP66 standards. This not only involves architecture that prevents dust and water from entering but also includes fully detachable belts that can be easily cleaned. The IP66 rating also allows for washing with powerful water jets.

In more demanding production environments, such as the canning industry, where the machine must be fully sanitized with high-temperature and high-pressure jets, the machine must be built with chain belts instead of standard belts, a special protective enclosure for the control panel, and pressurized motors. This makes it compliant with IP69K, the highest protection rating in its category.