16 December 2024

5 useful tips for choosing the most suitable metal detector

Guide to choosing an industrial metal detector: discover how to improve quality and safety in your production line

Conveyor weighing systems: advantages and sectors of use

28 May 2024

Conveyor weighing systems are indispensable in many production sectors to obtain fast and accurate weighing of raw materials, semi-finished and finished products. These systems allow you to precisely control the dosage of products, ensuring that they fall within the predetermined weight ranges and identifying any anomalies in production.

Among the various industrial weighing systems, checkweighers are particularly useful machines in all industrial sectors that require compliance of products with specific production standards and safety and quality regulations, such as the food and pharmaceutical industry.

Checkweighers are designed to weigh products in motion, directly on the production lines, ensuring a continuous and accurate quality control. They are equipped with high-precision load cells and advanced control systems, which allow you to detect even the slightest weight changes. This is especially useful to ensure that each individual product falls within the predetermined tolerance limits, minimizing waste and optimizing overall production efficiency.

Let’s see in more detail what are the advantages of conveyor weighing systems and the main application possibilities in different sectors.

Conveyor weighing systems offer many advantages, going beyond simple weighing accuracy, helping to optimize production processes and ensure compliance with strict quality standards.

One of the main advantages of checkweighers is the efficiency and speed of the weighing process. These systems can quickly and accurately weigh a wide range of products without interrupting the production flow, increasing overall productivity and reducing machine downtime. In addition, due to the accuracy of weighing and the precise weight classification, they reduce product waste. This entails considerable economic savings, also contributing to the environmental sustainability of production processes, since it significantly decreases the amount of non-compliant products, and therefore to be discarded.

Checkweighers are also essential to ensure the safety and regulatory compliance of products. The ability to record detailed weighing data allows companies to carry out a strict control on the product's quality and to demonstrate compliance with safety and quality regulations. This increases the brand value and the image of the company itself.

A further advantage of checkweighers is their flexibility and adaptability to different production lines. These machines are available in different configurations and can be adapted to the specific needs of different types of production, according to the characteristics of the products to be weighed, the working environment and the certifications required. The ability to obtain tailored solutions allows companies to optimize and speed up processes, regardless of the type of product or production volume.

Checkweighers also offer advanced features that allow you to collect and analyze data in real time. This facilitates the control of the performance of the production process and allows you to quickly identify any problems, favoring a continuous improvement in production efficiency.

Automating the production process can also reduce the need for manual product control. In this way it is possible to achieve significant savings on labor costs and to use resources in other strategic and value-added activities. In addition, the reduction of manual intervention significantly reduces the risk of human error, improving the accuracy and overall efficiency of production processes.

Industrial weighing systems can be used in many sectors thanks to their ability to accurately measure the weight of products in real time and ensure that they meet all quality and compliance standards.

One of the main areas of use is the food industry, where weighing accuracy is crucial to ensure that each package contains the exact amount of product declared. This not only ensures compliance with the European Directive 1976/211/EEC, transposed in Italy by Law n. 690 of 1978, in compliance with the net weight indicated on the package, but also helps to maintain consumer confidence, reducing waste and optimizing production efficiency.

Customers expect the purchased product to match exactly what is indicated on the label. The presence of less product than what is on the packaging could cause complaints from consumers and have negative repercussions on the credibility and image of a brand. A quantity of product in excess, on the contrary, could cause consistent economic damages for the producing companies.

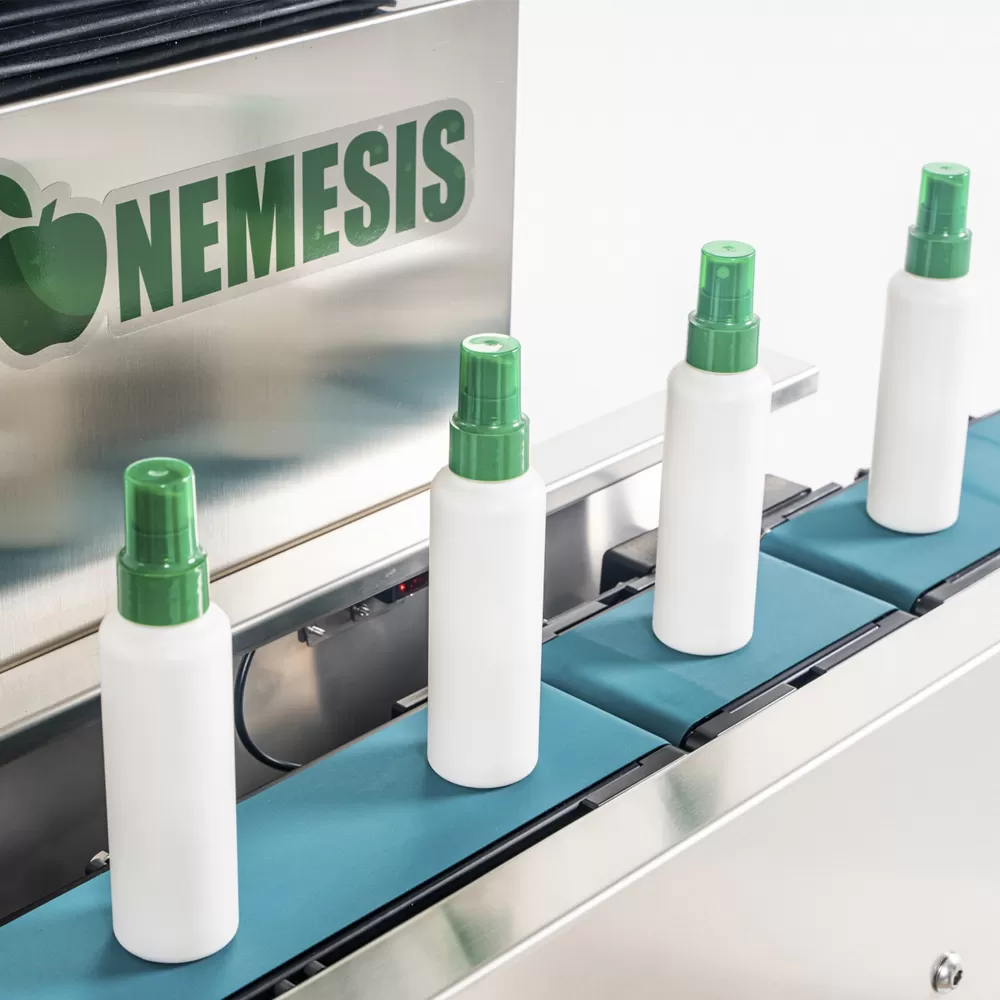

Checking the weight of products using automated weighing systems is also crucial in the cosmetic industry, for example for inspecting the contents of bottles of creams, lotions or shampoos, but also lighter products, such as body sprays. The high degree of accuracy of the checkweighers allows to ensure that each bottle contains exactly the amount declared on the label, moving the products on the weighing belt and discarding those that do not conform with the utmost precision and safety, without interrupting or modifying the packaging line in any way.

The pharmaceutical industry also requires a high level of accuracy in product inspection and quality control. In this area, online weighing systems are essential to ensure a correct dosage of the ingredients of medicines and that they strictly comply with the regulations provided by the industry, preventing errors that could compromise consumer safety. Checkweighers allow you to precisely check the filling level of the packages and the weight of medicines, identifying non-compliant weights even in lightweight products such as tablets or eye drops bottles. In addition, they also allow you to check the integrity and completeness of container boxes, detecting the possible lack of components such as blisters or instruction leaflets.

The traceability offered by inline weighing systems is also crucial for the detailed and safe management of production batches, facilitating product recalls if necessary.

In the chemical industry, checkweighers play a crucial role in ensuring the accuracy and safety of production processes. These machines can be used to check the weight of a wide range of chemicals, from raw materials to finished products, even in particularly aggressive working environments, ensuring that each unit falls within the specified weight limits. Precision is critical in this area, as even the slightest variation in chemical dosing can have significant consequences on the quality of the final product and on process safety. For example, in the production of pesticides or cleaning products, incorrect dosages can compromise the effectiveness of products or, worse, make them dangerous for use. Checkweighers help to avoid these risks by providing constant and accurate control throughout all stages of production.

Thanks to their ability to operate in real time, checkweighers also allow you to quickly identify and correct in real time any anomaly in the weight of products, minimizing waste and improving operational efficiency. For example, if an abnormal weight change is detected during production, the system can immediately report the error, allowing operators to take prompt action to correct the problem. If the sorting machine is equipped with the specific software, it can automatically adjust the dosage of the dosing machine upstream, without any human intervention. This not only improves the quality of the final product, but also reduces the costs associated with waste and re-processing.

Purchasing Nemesis belt conveyor weighing systems is a strategic and advantageous choice for any company that wants to ensure the highest quality and conformity of its products. Nemesis checkweighers are designed to allow 100% control of the net weight of products, ensuring full compliance with all legal requirements in force on the market. In addition, they allow to:

Using our simulator you can quantify the potential savings you could get by installing a Nemesis checkweigher in your production line. By simply entering the unit cost of the product, the number of pieces produced per minute from the line and a realistic hypothesis of the excess product that could occur during the production process, the simulator will provide you with a detailed analysis, showing the benefits you could have in terms of savings on a daily and annual basis.

News & Events

We'll be happy to follow-up your request within 24 hours